|

| [Special Applications] 특수한 용도의 완제품 및 부속 일람 |

|

|

|

| 글쓴이 : 다일IBC

날짜 : 09-03-22 01:00

조회 : 28409

|

|

|

Flexible Tube Assemblies

Conax Technologies Flex-Tube Assemblies protect wires from mechanical abuse. They are available in any length, factory assembled and furnished complete with end fittings (standard male or female pipe thread). Standard end fittings are plated brass or steel. Stainless steel Conax Technologies Packing Glands may be substituted at additional cost.

Interlock construction uses galvanized steel for 3/4" OD and brass for 3/8" OD, both with overall polyvinyl covering.

Ordering Notes:

To order cable and connectors only, order as follows:

FT4-M30

To add a terminal head, order as follows:

B2(FT4-M30), .25NPT

To order as part of a complete assembly, order as follows:

J-SS12-U-B2(FT4-M30)-12.00"

Multiple Probe Assemblies

Multiple probe assemblies terminating into a single T7 or other terminal heads are available. Consult the factory for details or request the Conax Pressure and Vacuum Sealing Assemblies catalog.

To order, for example, four thermocouple probes of varying lengths, terminating into a single terminal head, the following catalog number would be used:

Example: K-SS12-U-T7(MHM4B4L)-155.00", 162.00", 169.00", 176.00"

Fast Response RTD

For applications requiring the accuracy of an RTD combined with a response time approaching that of a thermocouple, Conax Technologies offers this fast-response design. The RTD element is installed directly into a tight-fitting machined silver tip, maximizing thermal transfer. The diameter of the tip can also be adjusted to maintain lateral contact, making this the preferred design to replace an RTD into an existing field-installed thermowell with a non-standard bore.

Extra Long Thermocouple Assembly

Thermocouple assemblies with extra long lengths of bendable, sheathed thermocouple probe are available. Simply indicate the active length as shown:

Example: J-SS25-U-T3-400.00"

Roll Temp Assemblies

Conax Technologies Technologies' Roll Temp Sensor Assemblies provide repeatable monitoring of surface temperatures on drums, rollers or other moving surfaces. They are ideal for detecting temperature variations in continuous process applications, such as plastic-film processing, wire manufacturing and painting processes.

Compact and easy to install, Roll Temp Assemblies are furnished with Conax B2 terminal heads. Brass contact buttons, flush-mounted in a spring-loaded Teflon plunger, provide excellent thermal transfer to the temperature sensor. They are available in all base metal thermocouple calibrations. Three models are offered.

Sliding Contact Assembly - Catalog Type RT

- Designed for temperature sensing on surface speeds up to 900 ft. per minute

- Temperature range: -90? F to +500? F (-68?C to +260? C).

- 1/2 lb. spring force on sensor

- Not available in special tolerances

Example: For a Chromel-Constantan thermocouple, the catalog number would be RT-E.

High-Speed Assembly - Catalog Type HSRT

- Features a mounted roller bearing for surface speeds up to 1000 ft. per minute or use on highly polished surfaces that might be damaged by a sliding contact

- Bearing outer race is in contact with the process and the inner race is in intimate contact with the sensor hot junction

- Optional sterling silver roller is available for fast response at slower speeds

- Temperature range: -90? F to +400? F (-68? C to +204? C)

- Not available in dual or triple configurations or in special tolerances

Example: For an Iron-Constantan thermocouple, the catalog number would be HSRT-J.

High-Temperature Assembly - Catalog Type HTRT

- Temperature range: -90? F to +700? F (-68? C to +371? C)

- Similar in construction to Type HSRT except that continuous surface contact is assured by use of a Conax Technologies spring-loaded packing gland assembly

- Speeds up to 1000 ft./min.

- Available in all base metal calibrations

- Not available in dual or triple configurations or in special tolerances

Example: For a Chromel-Alumel thermocouple, the catalog number would be HTRT-K.

Note: Due to factors of friction and dynamic properties of the environment, these sensors may not conform to ANSI/ASTM published tolerances. Mounting bracket dimensions: 4-1/2" x 1" x 1/8" with four 0.250" diameter mounting holes over a 2-1/2" length.

Teflon-Coated Probe Assembly

Designed for immersion in corrosive fluids, this thermocouple or RTD assembly features a Teflon-coated sheath for increased corrosion protection. Leadwires are mechanically protected by a stainless steel braid (T4). The assembly is normally terminated with a Conax Technologies PJ male plug. Teflon coating can be applied to most sensor probe assemblies presented in this catalog.

Conax Technologies Con-O-Clad® Bulk Thermocouple Wire

Conax Technologies manufactures our exclusive mineral insulated (MgO) Con-O-Clad® bulk material for single and multiple pair wires. This is available in all ASTM base metal thermocouple calibrations in sizes from 0.040" to 0.375" diameters. Other non-standard material combinations can be furnished for special requirements.

Pipe Clamp Thermocouples

Conax Technologies stainless steel pipe clamp assemblies assist in obtaining accurate readings of outside pipe temperatures. They can be used wherever direct immersion probes are impractical or undesirable or where extreme corrosion is a problem.

- Outside application leaves high-pressure lines unbroken

- Easily installed - simply place the opened clamp around the pipe, slip the band end into the worm-gear housing and tighten with a screwdriver.

Pipe Clamp/Sheathed Thermocouple

The catalog number for a pipe clamp/sheathed thermocouple with a terminal head is indicated by placing the pipe clamp catalog number immediately after the terminal head designation. For example, an adjustable pipe clamp thermocouple with a 0.125" diameter 304SS sheath, using an Iron-Constantan grounded junction thermocouple 18" long and terminated with a B2 head for a 2" pipe would have this catalog number:

Example: J-SS12-G-B2-CL40-18.00"

Pipe Clamp/Wire Thermocouple

Pipe clamp thermocouples are also available in an alternative design consisting of a clamp with 20 gauge thermocouple wire (Types J, K, E & T) and a spring vibration dampener. Standard wire length is 18.00". Longer lengths are available. To order this assembly, indicate the pipe clamp catalog number, followed by the calibration and optional wire length if applicable (if nothing is indicated, 18" standard will be supplied).

Examples: CL-10-J or CL-10-J-36.00"

Speed Wells

Speed well assemblies enclose the sensor element in a stainless steel protection tube with the tip sealed with a homogenous weld. This design permits a very fast response rate, as the stainless steel protection tube provides low mass and low thermal inertia. The thermocouple is sealed inside the speed well and protected from oxidation or corrosion. The thermocouple wire is insulated with silicone impregnated fiberglass for temperatures up to 900° F (482° C). Ceramic insulation can be provided inside the well for temperatures above 900° F. Speed wells are suitable for use at pressures from vacuum to 3000 psi. Temperatures range from -300° F to 2000° F (-184° C to 1090° C), depending on the pressure.

Triple Point Sensors

Triple Point Temperature Sensors allow monitoring of three separate temperature points within a vessel using a single probe. Originally designed by Conax for use during the calibration of epitaxial reactors, this technology is now used in a range of industrial process control applications. A tapered sheath ensures the proper location of the measuring junctions.

The original application uses Tungsten/Rhenium thermocouple wires to supply very accurate operation in a 1200° C environment. An inert-gas backfill protects the thermocouple wires from high temperature oxidation.

Specialty Tip Configurations

In addition to our standard tip configurations, the following are available for special applications:

PG - Pointed, Grounded PU - Pointed, Ungrounded

- Designed for easy insertion

- Machined with a 60° included angle

- Ideal for taking fast, repetitive readings in penetrable materials

- Not designed for use in human or animal applications

FRU - Fast Response, Ungrounded

- Uses a sterling silver tip for contact and surface temperature measurements where optimum response time and rugged construction characteristics are required.

EP- Exposed, Protected

- Designed for applications demanding fast response.

- The element is exposed within its cavity, and media flow reaches it through drilled orifices.

- Insulation is completely sealed with epoxy resin against liquid or gas penetration.

- Maximum service temperature: 300? F (150? C).

Trimmable Sheath RTD Assembly

Trimmable RTDs provide versatility, accuracy and ease of use in one rugged unit, with a 4-wire lead configuration that provides measurements of the highest precision. The trimmable RTD's easy, cut-to-fit feature allows the user to alter the length of the RTD sheath to fit into various thermowells, pipewells and tubewells. The stainless steel sheath is trimmable, using a commercially available tube cutter, down to a length of 6".

The leadwire is constructed of 24 AWG Teflon®-insulated, stranded wire, color coded Red/Red White/White. The platinum 100 ohm element complies with DIN 43760, and IEC 751, Class B tolerance.

- High accuracy

- Stock a single sensor for various applications

- Fast delivery

- 100 ohm Platinum RTD Sensor

- Maximum service temperature: 400° F (204° C)

- Available Lengths:

Minimum Sheath Length - 6 inches

Maximum Sheath Length - 5 feet

Maximum Leadwire Length - 20 feet To order, specify the leadwire length in inches, followed by the sheath length in inches: Example: RTD43W4-SS25-TR(120")-24"

Miniature Bearing Sensors

The bearings of industrial rotating equipment operate under arduous conditions - often for considerable periods of time. The most reliable indicator of bearing condition is the temperature of the metal beneath the shoe. Recognition of rising temperature can provide a warning of the breakdown of the lubricating oil film; thus allowing machine shutdown and maintenance to take place - avoiding the probable catastrophic failure of the bearing and possible damage to its mounting. Conax Miniature Bearing Sensors provide a simple and cost-effective method to monitor bearing temperatures. Features:

- For embedded applications in rotating machines

- RTDs - 100 ohm platinum, 0.00385 ohm/ohm/°C

- Thermocouples types J, K, T & E

- Single and duplex sensors

- Various styles and sizes

- Operating Temperature: to +250° F (+120° C)

RTD & Thermocouple Assemblies for Hazardous Locations

CBT 100, CBT 200 and CBT 300 Series assemblies meet U.S. and Canadian standards (NRTL/C, CSA) for use in hazardous locations as defined by NEC Class 1, Division 1, Groups B, C & D; Class II, Groups E, F & G; and Class III.

CBT 100 Series sensor-terminal head assemblies are available in all thermocouple calibrations and in RTD assemblies with 100, 200, 500 and 1000 ohm platinum, 10 ohm copper or 120 ohm nickel elements. Assemblies are available with stainless steel or Inconel sheaths, a W8 mounting fitting and explosion-proof terminal head with terminal strip. An optional 4-20mA transmitter can be provided.

CBT 200 and CBT 300 assemblies are NEC-compliant replacement probes for use with UL and CSA-approved terminal heads in hazardous locations. CBT 200 provides a W8 fitting for attachment to the terminal head and to the vessel. CBT 300 provides a W7 fitting for attachment to the terminal head. A separate adjustable fitting is required to attach the probe to the vessel.

Certificate No. LR111664-1

Sensor Probes with 90° Bends

Thermocouple and RTD sensors are available with a single right angle (90°) bend in the sheath. This is indicated by adding a dimension and the letter "R" to the catalog descript-xion. The dimension indicates the distance from the tip of the sensor to the start of the bend. The standard bend radius is 1/2" for 0.062" diameters and smaller, 3/4" for 0.125"-0.250" diameters, and 2" for 0.375" diameters.

Example: RTD43W3-SS25-T1-12.00", 4.50R

In general accepted practice, the bend should never start closer to the tip than 3" for any RTD; or for thermocouples, 1/2" for 0.062" and smaller probe diameters; 2" for 0.375" probe diameters or 4 times the sheath diameter for 0.125" through 0.250" probe diameters. The termination should not be closer than 3/8" from the completion of the bend. For 0.375" probe diameters, the termination should be no closer than 2" from the bend. Type ERTD and MRTD assemblies should never be bent. Other bend radii and multiple bends are available as custom items. Consult factory.

Safety Well Thermocouple Assemblies

Conax WTG and XTG thermocouple assemblies employ Transducer Glands (TG) as the component part for sealing sensor thermocouple wires and the primary environment seal. The seal prevents contamination of the electronics within the terminal head and leakage of gas or liquid into the control room.

- WTG - Grounded Junction

- XTG - Bare Wire Junction

Assemblies consist of base metal thermocouple wire (Types E, J, T and K) surrounded by hard-fired alumina insulators. Use of hard-fired insulators eliminates low IR problems often found in MgO mineral insulated wire junctions. Exposed junction thermocouples offer excellent temperature measurement speed of response.

The Conax TG gland uses Conax-designed "soft sealant" technology to seal on the bare wires. It is available with Lava, Teflon, Neoprene or Viton sealant materials. Selection of the proper sealant is dependent on the application. For details, request Conax's Pressure and Vacuum Sealing Assemblies catalog or contact a Conax sales engineer. The protection tube is welded to the gland body on the mounting thread side. The other end of the gland is attached to the terminal head.

Thermistor Assemblies

Thermistors are semiconductive devices whose electrical resistivity is designed to vary in a definite desired manner with temperature. Their temperature coefficient of resistance is approximately ten times that of metals, providing very high sensitivity to small temperature differences. Thermistors offer very high sensitivity over a narrow temperature range, with very good stability and repeatability.

Conax provides thermistors in easy-to-use probe form to fit any need. Conax engineers welcome the opportunity to assist you in applying this technology to your applications.

Integrated Circuit Sensors

An integrated circuit sensor uses a small temperature transducer to convert temperature input into a proportional current output. These sensors are designed for use in temperatures from -67° to 302° F (-55° to 150° C) where solid state reliability and accuracy are required. Sensor output (within this temperature range) is 1µA/°K. These sensors are also useful in remote sensing applications, as the high impedance current output makes them insensitive to voltage drops over long lines.

Multiple Quick Disconnect

Catalog Type MQD

Multiple Quick Disconnect assemblies are available for E, J, T and K calibrations. This six-pin configuration is polarized for each thermocouple type to eliminate sensor mismatch. The plug and receptacle use base metal thermocouple contacts, molded and staked in phenolic inserts. The plug is brazed to the thermocouple probe and filled with epoxy. The receptacle features Teflon-insulated twisted shielded pair conductors. When mated, the connector is waterproof. The termination and sensor sheath are supplied as an integral unit.

Example: E-SS25-2U-MQD-MK250A-12.00"

Weld Pads

To facilitate welding thermocouples to surfaces in the field, Conax Technologies can fit the measuring junction with a weld pad. Flat or curved pads are 0.125" thick x 1.00" square and are available in 304 or optional 316 stainless steel. Flat pads may be welded flat (Style F) or perpendicular (Style P). Curved pads may also be welded flat (FC) or perpendicular (PC) and offer a choice of radius of 0.567" (for 1" nominal pipe) or 0.875" (for 1.5" nominal pipe).

Armored Assemblies

Sensor assemblies can be provided with helically wound stainless steel interlocked armor cable for exceptional mechanical strength, flexibility and RFI/EMI resistance. One of our more popular models consists of a T3 assembly terminated with a Conax Technologies PJ male plug. This assembly is ideal for rugged service in physically demanding environments where the leadwires could be exposed to compression and wire abrasion.

Example: J-SS12-G-T3(ARM 20FT)-PJC-12.00"

High Density Feedthrough Assemblies

High Density (HD) assemblies consist of a stainless steel tube swaged over 12, 24, 40 or 60 bundled Teflon-coated thermocouple grade and/or copper wires, providing a continuous wire feedthrough for thermocouples, RTDs or low voltage instrumentation. No epoxy or potting is used in the construction. The assembly can be furnished with or without junctions and comes standard with 24 inches of leadwire on each end. Longer wire lengths can be supplied as required. A single high density feedthrough can pass through a Conax packing gland for environmental sealing. Greater density through a single port can be achieved by using a multi-hole metal gland that accommodates multiple HD assemblies. HD18 - 0.187" diameter, 12 conductors HD25 - 0.250" diameter, 24 conductors HD31 - 0.312" diameter, 40 conductors HD37 - 0.375" diameter, 60 conductors

- Sheath Material: 300 Series SST, 4.5" nominal length

- Temperature Range: -112° F to +250° F (-80° to +120° C)

- Vacuum Rating: 5 x 10-6 mm HG @ 68° F (20° C)

- Leak Rate: 1 x 10-9 scc/sec He @ 68° F (20° C), 1 atm. applied

- Voltage Rating: 100 VDC

- Amperage Rating: 500mA

- Feedthrough Pressure Rating @ 68° F (20° C): 5000 psi (345 bar)

TG Gland with 24 AWG Insulated Leadwire

This assembly consists of a Conax Technologies manufactured transducer gland (TG) with a Teflon sealant and Teflon-coated thermocouple grade or copper wires. Typical applications include the sealing of wires exiting compressor bearing housings, pressure vessels, instruments, furnaces and reactors. The gland is furnished with 24" of wire on each side. Longer wire lengths can be furnished as required.

Temperature Range: -300° to +450° F (-184° to +232° C)

Pressure Rating @ 68° F (20° C): Vacuum to 4400 psi (300 bar)

TG Gland with High Temperature Wires

Transducer gland assemblies with fiberglass-insulated thermo-couple wire are specially designed for applications where the sensor wire is exposed to process temperatures reaching up to 900° F (482° C). This assembly is particularly targeted for use with vacuum and/or inert gas back-filled furnaces with vessel wall temperatures up to 200° F (93° C) and pressures not exceeding 300 psi. The assembly consists of bonded fiberglass-insulated/silicone impregnated thermocouple grade wires on the body side, with stripped bare wires passing through the Conax-manufactured transducer gland. An alternative high-temperature fiberglass for Type K wire is also available with temperature capabilities up to 1400° F (760° C). Sleeved insulation material on the wires exiting the cap side may be fiberglass/silicone impregnated, Teflon® or polyolefin. Available gland sealant materials are Viton® and Teflon.

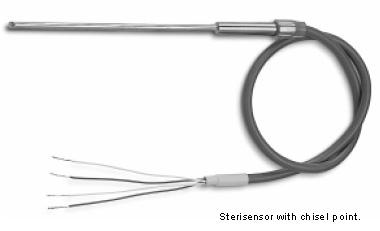

Sterisensor™ Chamber/Load Sensor Assembly

Sterisensor withstands the environmental conditions found in pharmaceutical autoclave chambers. Sterisensor’s engineered moisture seal prevents the ingress of moisture which is the leading cause of failure.

Thermocouple Type T or RTD, 100 ohms @0°C, .00385 ohms/ohms/°C calibrations are available, sensor lengths and diameters are configured to meet application requirements.

Sterimaster® Chamber/Load Sensor Assembly

The environmental conditions found in pharmaceutical autoclave chambers are extreme for any equipment. These conditions are a major cause of sensor failure in chamber/load probes due to the ingress of moisture into the sensor and the unacceptable leakage of steam/condensate through the bulkhead connection.

The Sterimaster Chamber/ Load Sensor has been designed to withstand these conditions and offers a reliability factor surpassing anything previously obtainable. Every weld undergoes NDT examination and each completed assembly is leak tested.

Steriwire Thermocouple

Steriwire continuouse-wire thermocouples feature a Type T (Copper/Constantan) thermocouple with special limites of error, attached to a nearly unlimited length of Teflon®-insulated stranded thermocouple wire. Optional Teflon tipping provides electrical isolation of the thermocouple function from the environment or product. One-inch tipping is standard, but tipping up to 6" long (in one-inch increments) is available. The simplicity of construction allows these junctions to be configured in the field if required. Plug&Jack terminations made of molded thermoset compounds are also available in miniature and standard sizes.

www.daiLibc.co.kr

|

|

|